RT40B Rebar Thread Rolling Machine

Machine Function:

AEONO RT40B REBAR THREAD ROLLING MACHINE is used to strip rebar rib first and roll parallel thread on rebar end. After that two threaded rebar sectors are connected by Rebar coupler. It can process HRB335, HRB400, HRB500 reinforced bar with diameter 16–40mm. The max thread length is 80mm.

Machine Advantages:

Rebar rib peeling straight thread overcomes defects of strapping, welding, extrusion, taper thread, upsetting straight thread, and combines the respective advantages

1) High precision thread

2) High connection strength

3) High construction efficiency

4) Easy installation, operation and maintenance

5) Small volume, light weight, power consumption

6) Low investment for the machine

7) Shortening construction period

8) Reduce the labor intensity of workers

9) Reasonable structure, reliable performance

10)Full-tension splice, 100% bar break under high tensile strength

It is the upgrading technology of steel bar connection in the construction industry.

Workshop & Warehouse

Operationg

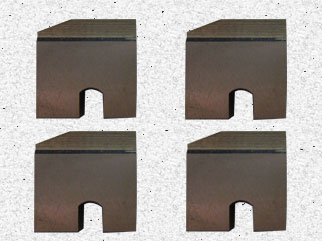

Main Spare Parts

Cutting Blade: It is used to cut ribs.

Thread Roller: it is used to roll thread on the rebar end.

Application

Packing Detail

RT40B Rebar Thread Rolling Machine Parameters

| Model: | RT40B | Rebar Diameter: | 12-40MM |

| Motor Power: | 4KW 8A | Voltage: | 3-380V 50HZ |

| Thread Angle: | 75°, Customized | Thread Pitch: | 1.75-3.5MM |

| Spindle Speed: | 48-82 r/min | Max Thread Length: | 100MM |

| Dimension: | 1*0.7*0.9M | Net Weight: | 400kg |

| Certification: | ISO9001-2008 | Package: | Wooden Case |

Leave A Comment